Did you know that integrating Salesforce with an inventory management system can significantly improve your inventory processes and drive better customer satisfaction?

Salesforce, a leading customer relationship management (CRM) platform, offers a wide range of applications to help businesses streamline their sales, marketing, and customer service operations. However, one area where Salesforce truly excels is inventory management. By integrating with inventory management systems, Salesforce empowers businesses to optimize their inventory processes, reduce costs, and ensure superior customer satisfaction.

But how exactly can Salesforce’s inventory management system benefit your business?

Let’s take a look at some statistical data to illustrate the impact of implementing a Salesforce inventory management system. According to a recent study by Gartner, companies that effectively manage their inventory experience an average increase in revenue of 3% to 7% and a decrease in costs of 5% to 10%. Additionally, businesses that incorporate inventory management technology see a 50% reduction in stockouts, leading to higher order fulfillment rates and improved customer loyalty.

By starting your inventory management journey with Salesforce, you can take advantage of a wide range of benefits, including real-time inventory visibility, efficient order fulfillment, reduced costs, improved customer satisfaction, and seamless integration with other business systems.

In this blog, we will provide an in-depth guide on how to implement and using the Salesforce inventory management system, covering various aspects such as its benefits, features, and implementation process.

Understanding Salesforce Inventory Management System

Salesforce Inventory Management System is a system that helps businesses track and manage their inventory efficiently. It allows businesses to keep track of their stock levels, monitor product movements, and automate inventory-related processes such as ordering and stock replenishment.

Now, here’s a common formula that can be used in Salesforce Inventory Management System to calculate available stock:

Available Stock = Initial Stock + Purchase Orders – Sales Orders

Initial Stock: The starting quantity of a product in stock.

Purchase Orders: The total quantity of the product ordered from suppliers but not yet received.

Sales Orders: The total quantity of the product that has been sold but not yet fulfilled.

Consider the example of a global e-commerce retailer. Before implementing Salesforce’s inventory management system, they faced challenges such as stockouts, inaccurate inventory tracking, and delays in order fulfillment.

However, after integrating Salesforce with their inventory management system, they experienced a 20% reduction in stockouts, a 30% increase in order fulfillment rates, and a 15% improvement in customer satisfaction levels.

Read Our Old Blog : Enhance Your App Development Workflow with Salesforce Communities

Benefits of Salesforce Inventory Management System

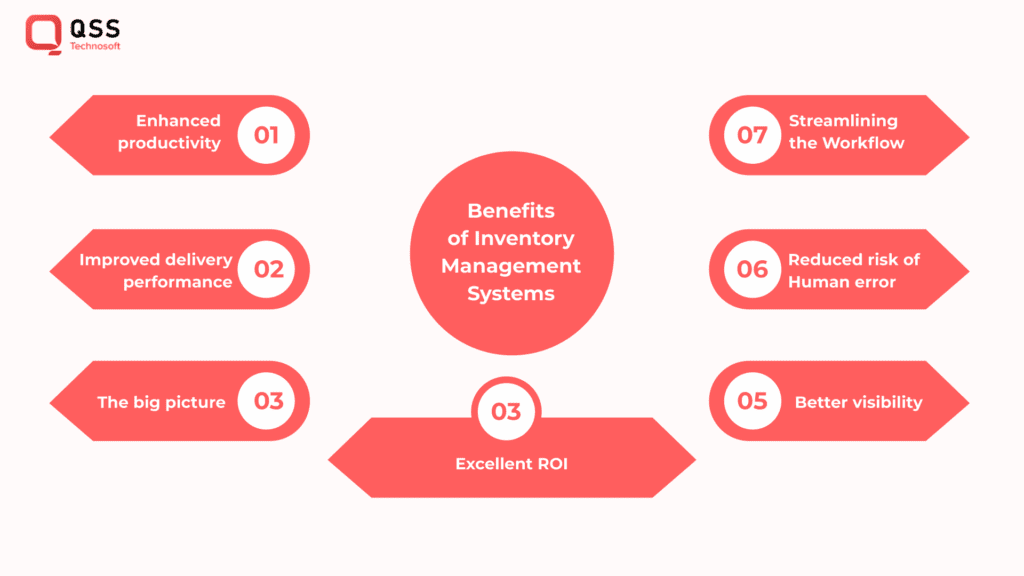

There are many benefits of implementing and using Salesforce Inventory Management System. Let’s take a look at some below.

Real-time Inventory Visibility: Salesforce enables businesses to have real-time visibility into their inventory levels, including stock availability, location, and movement. This visibility helps businesses make informed decisions about stock management, order fulfillment, and replenishment.

Efficient Order Fulfillment: With Salesforce inventory management system, businesses can automate their order fulfillment processes by setting up rules and alerts based on inventory levels. This ensures that orders are fulfilled quickly and accurately, minimizing the risk of stockouts and improving customer satisfaction.

Reduced Costs: By optimizing inventory levels and streamlining processes, Salesforce inventory management system helps businesses reduce costs associated with carrying excess inventory or experiencing stockouts. It also eliminates the need for manual tracking, reducing labor costs and human errors.

Improved Customer Satisfaction: Salesforce inventory management system ensures accurate and timely order fulfillment, reducing the likelihood of backorders or delays. This leads to improved customer satisfaction and loyalty.

Integration with Other Systems: Salesforce can integrate seamlessly with other business systems such as ERP (Enterprise Resource Planning) and e-commerce platforms, enabling a holistic view of your inventory across different channels. This integration further enhances inventory management capabilities and facilitates smooth data flow.

Read More :Uncover the 15 Best Testing Practices for Salesforce App Development

Key Features of Salesforce Inventory Management System

- Inventory Tracking:

Salesforce enables businesses to track and manage inventory across multiple locations and channels. It provides visibility into stock levels, stock movements, and stock history, helping businesses make data-driven inventory management decisions.

Example: A multinational e-commerce platform, using Salesforce, manages its inventory of electronic gadgets. The system allows real-time tracking of smartphone stock across warehouses globally. When a new iPhone model is launched, the platform can instantly view stock levels in each warehouse, ensuring prompt distribution to meet the surge in demand.

- Order Management:

Salesforce allows businesses to manage orders from initiation to fulfillment. It automates order processing, tracks order status, and provides alerts for low stock levels or delays. This ensures efficient order fulfillment and improves customer satisfaction.

Example: A clothing retailer relies on Salesforce for order management. When a customer places an order online, Salesforce automates the entire process—from order confirmation to shipment tracking. If a particular item is out of stock, the system alerts the customer service team to proactively communicate with the customer, offering alternatives or providing realistic delivery timelines.

- Supplier Management:

Salesforce inventory management system includes supplier management capabilities, allowing businesses to manage their relationships with suppliers, track supplier performance, and consolidate purchase orders. These features help businesses maintain optimal inventory levels and negotiate better terms with suppliers.

Example: A food and beverage distributor uses Salesforce to manage relationships with suppliers. The system tracks supplier performance metrics, such as on-time deliveries and product quality. If a supplier consistently meets high standards, the company negotiates better terms, ensuring a steady supply of fresh produce and maintaining a level in market.

- Reporting and Analytics:

Salesforce provides powerful reporting and analytics capabilities to analyze inventory data, track key metrics, and identify trends. Businesses can generate reports on stock levels, sales performance, order fulfillment rates, and more. This data-driven approach helps businesses optimize inventory management and make informed decisions.

Example: An automotive manufacturer employs Salesforce for reporting and analytics. By analyzing historical data, the system identifies patterns in the demand for specific car models. If SUVs are consistently popular during certain seasons, the company adjusts production schedules and marketing strategies accordingly, maximizing sales and minimizing excess inventory costs.

Implementation Process of Salesforce Inventory Management System

One key functionality that Salesforce offers is the ability to implement an inventory management system, which helps organizations effectively track and manage their inventory levels. We will outline the step-by-step process of implementing a Salesforce inventory management system.

Step 1: Assessment and Planning

Identify the business requirements: Evaluate the specific needs of the organization regarding inventory management, including inventory tracking, stock replenishment, and order fulfillment.

Evaluate existing inventory management processes: Assess the current manual or outdated systems in place and determine how Salesforce can streamline and automate these processes.

Define key performance indicators (KPIs): Establish KPIs such as inventory turnover rate, stock accuracy, and order fulfillment speed to measure the success of the inventory management system implementation.

Set project goals and objectives: Define the desired outcomes of the implementation, such as improved inventory visibility, reduction of stock-outs, and increased efficiency.

Step 2: Design and Configuration

Inventory data model design: Design a data model that captures key inventory-related information, such as product details, stock levels, warehouse locations, and transaction history.

Customization and configuration: Configure Salesforce objects, fields, and workflows to align with the organization’s specific inventory management requirements. This includes creating custom fields for storing inventory data such as SKU, barcode, and stock levels.

Workflow automation: Use Salesforce Process Builder and Workflow Rules to automate inventory-related processes, such as generating purchase orders when stock levels fall below a certain threshold or initiating shipping notifications when orders are fulfilled.

Integration with other systems: Integrate Salesforce with other systems such as ERP or warehouse management systems to ensure seamless data synchronization across the organization.

Step 3: Data Migration and Validation

Data extraction: Extract inventory data from the existing system(s) or spreadsheets and prepare it for migration into Salesforce. This may involve using data export tools or writing custom data extraction scripts.

Data cleansing and transformation: Cleanse and validate the data by removing duplicates, correcting inaccuracies, and ensuring data integrity. Data cleansing tools or Excel macros can be employed for this purpose.

Data migration: Import the cleansed inventory data into Salesforce using tools like Salesforce Data Loader or through API integrations. Map the data to the corresponding fields in the Salesforce data model.

Data validation: Perform data validation checks to verify the accuracy and completeness of the migrated inventory data. This includes reconciling the migrated data with the original system(s) to ensure data consistency.

Step 4: User Training and Acceptance

User training sessions: Conduct training sessions to educate users on how to navigate the Salesforce inventory management system, perform tasks such as updating stock levels or processing orders, and generate inventory reports.

User acceptance testing (UAT): Engage users to test the system’s functionality and user-friendliness. Users should verify that the system meets their inventory management requirements and address any potential issues or missing features.

Address user feedback and issues: Gather feedback from users during UAT and iteratively address any concerns or modifications required to optimize the system for their needs.

Step 5: Deployment and Go-live

Deployment planning: Develop a deployment plan that outlines the deployment steps, timeline, and resource allocation required for a successful go-live.

User access and security: Configure user access rights and permissions based on user roles and responsibilities. This ensures that only authorized personnel can access and modify inventory data.

System testing: Conduct thorough testing of the Salesforce inventory management system to ensure all components, integrations, and workflows are functioning correctly. This involves testing functionality such as stock level updates, purchase order generation, and inventory reporting.

Data migration to the production environment: Migrate the validated inventory data from the test environment to the live production environment, ensuring that all data is accurately transferred.

Go-live and post-implementation support: Enable the Salesforce inventory management system for live usage. Provide post-implementation support to address any issues or questions that may arise initially, such as data discrepancy or user adoption challenges.

Step 6: Ongoing Maintenance and Enhancements

Monitoring and performance optimization: Continuously monitor the performance of the Salesforce inventory management system and optimize its efficiency. This includes monitoring server response times, data synchronization, and system usability.

User support and training: Provide ongoing user support and additional training sessions to address any questions, resolve issues, and train users on new features or enhancements.

System enhancements: Regularly assess user feedback and business needs to identify opportunities for system enhancements or new features. This may involve enhancing inventory reports, adding new integrations, or streamlining workflows to further improve inventory management processes.

Conclusion

Implementing a Salesforce inventory management system can bring significant benefits to businesses. By following the implementation process outlined in this guide, businesses can successfully use the capabilities of Salesforce to streamline their inventory management processes, enhance decision-making, and drive business growth.

To ensure a successful implementation of your Salesforce inventory management system, partner with an experienced and reliable implementation partner like QSS Technosoft. We at QSS Technosoft has a team of Salesforce experts who can customize and configure Salesforce to meet your specific inventory management requirements. We offer end-to-end implementation services, from assessing your business needs to data migration, training, and ongoing support.

Take advantage of QSS Technosoft’s expertise to optimize your inventory management processes. Contact QSS Technosoft today for a consultation and propel your business towards efficient and streamlined inventory management.

Contact QSS Technosoft to start your Salesforce inventory management implementation journey.

We are proud to mention that our work has been recognized by leading B2B reviews and research platforms like GoodFirms, Clutch, MirrorView, and many more.