The construction industry, despite being one of the most significant contributors to global economic activity, has long grappled with inefficiencies that hinder its potential. Project delays, cost overruns, labor shortages, and safety concerns are common challenges that have persisted for decades. These issues, rooted in traditional construction methods, have led to project inefficiencies, strained budgets, and, in some cases, compromised safety standards.

However, the advent of digital technologies is offering a beacon of hope. The construction industry is increasingly embracing digital transformation to overcome these challenges, streamline operations, and enhance overall project outcomes. From leveraging data for better decision-making to integrating advanced technologies like AI and IoT, the construction sector is on the cusp of a revolution that promises to reshape its future.

Also Read:- What is Ripple Blockchain? Everything You Need to Know in 2024?

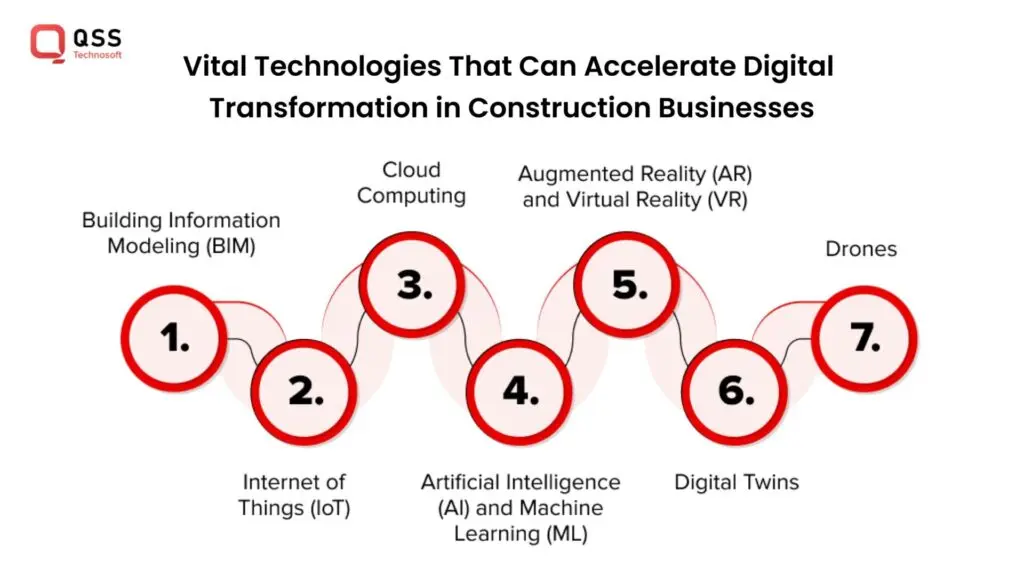

The key Technologies Driving Digital Transformation in Construction

Let’s discuss some of the technological stack that brings transformation in the construction industry-

Building Information Modeling

Building Information Modeling (BIM) is at the forefront of the digital transformation occurring in the field of construction. BIM is changing the ways construction projects are planned as well as planned and implemented. Through the creation of detailed visual representations digitally of the physical structure BIM lets engineers, architects, and contractors collaborate more efficiently, recognize the potential problems before they become apparent, and streamline your construction process.

The integration of BIM into 3D modeling and the digital twins also enhances the management of projects. Digital twins – virtual copies of physical assets that allow live monitoring and analytics, giving insight into the lifecycle of a building from concept to the point of completion, and even beyond. This integration can lead to more efficient construction methods as well as less waste and better project results.

Drones and Aerial Data

Drones are now a necessity for modern construction projects. These unmanned aerial vehicles are used for site surveying, monitoring progress, and ensuring accuracy in measurements. It give project managers immediate information, enabling them to make educated decisions and make adjustments as required.

For instance, drones can collect aerial images and make 3D plans of sites for construction, assisting team members to spot problems before they become serious. Drones’ use does not just improve the accuracy of data collection but increases safety by eliminating the requirement to conduct manual inspections in potentially hazardous zones.

Internet of Things (IoT)

The Internet of Things (IoT) plays a significant role in improving the safety of construction sites and monitoring the effectiveness of equipment. IoT-enabled sensors and devices can monitor the conditions of the environment as well as check the health of equipment, and protect workers in real-time.

Sensors can, for example, detect fluctuations in temperature or humidity levels. They can also detect other environmental variables that may influence construction materials and worker safety. They can also track the condition of equipment and alert maintenance personnel that machinery needs to be monitored. With real-time data, IoT devices enable proactive decisions, reducing the chance of equipment malfunctions and accidents.

Cloud-Based Project Management

Cloud-based platforms for managing projects are revolutionizing the method of managing construction projects. These platforms allow instant communication and collaboration between participants, regardless of their physical place of residence. Through the storage of project data within the cloud, team members are able to gain access to the most recent information, update their profiles and work on projects in a seamless manner.

Cloud-based solutions also offer an online repository for all project-related documents, which ensures that everyone is able to access the most current information. This improves communication and collaboration, but it also helps reduce the chance of errors caused by obsolete or insufficient data.

Augmented Reality and Virtual Reality

Augmented Reality and Virtual Reality are developing as powerful tools for design and planning for construction. AR lets project teams overlay digital models on physical spaces, allowing users to see how the structure will integrate into the surrounding environment. AR is particularly beneficial in design visualization, safety training as well as interactive planning for construction.

VR however provides immersive experiences that are suitable to train employees and prepare for environments with high risk. VR simulations simulate situations from the real world, allowing employees to test safety procedures and enhance their abilities without having to expose them to actual dangers.

Effect of Project Efficiency and Productivity

More Efficient Project Timelines

Digital tools such as BIM and IoT can significantly reduce project delays through better plan and execution. BIM provides a precise visualization of projects, which helps teams to spot issues earlier in the planning stage. IoT devices give real-time data which can help keep track of progress and make adjustments, if necessary, to ensure that projects are on the right the right track.

For example, using IoT sensors in project management software allows for real-time tracking of the materials and equipment. This makes sure that resources are readily available at any time, making it easier to complete the process of completing projects.

Better Collaboration

Cloud solutions simplify communications and cooperation between engineers, architects, and contractors. With a central repository for all project-related data, cloud-based tools make sure all parties are on the same page thus reducing the possibility of communication breakdowns and erroneous information.

These platforms also allow remote collaboration, which allows teams to collaborate even from different locations around the globe. This is especially beneficial for large-scale projects with multiple stakeholders and intricate coordination.

Real-Time Data Access

Real-time data access is enhancing the process of making decisions in construction. With the ability to get access to live information from sensors, drones and other equipment project managers can make quick and informed decisions to reduce delays and enhance results of projects.

For instance, real-time data from IoT sensors can be utilized to assess the conditions of the environment on construction sites. If the sensor determines that temperatures are excessively high or that humidity levels are low the project manager should quickly take action to protect the materials and ensure the safety of workers.

Automation in Construction

Automation plays a growing part in construction, with robotics employed for repetitive tasks such as bricklaying or concrete pouring. Robots can work quicker and more accurately than human laborers, enhancing efficiency and decreasing the risk of making mistakes.

Automation can also increase security by decreasing the requirement for workers to carry out dangerous tasks. For instance, robots can be used to put bricks in difficult-to-access areas as well as pour concrete within dangerous areas, which reduces the chance of accidents.

Enhancing Sustainability in Construction with Digital Tools

Energy-Efficient Designs

BIM helps construction teams to reduce energy use within buildings by providing accurate simulations of how the building will perform under different environments. This enables engineers and architects to make informed choices about materials as well as insulation and other elements that impact the efficiency of energy.

For instance, BIM can be used to test the impact of various building materials on energy consumption. By comparing the performance of different materials, teams can select the most efficient option and reduce the global environmental impacts.

Smart Materials

AI and IoT play a crucial role in developing and tracking the use of eco-friendly construction materials. AI algorithms can analyze data from past projects to identify the most sustainable materials, while IoT sensors can monitor the performance of these materials in real-time.

For example, IoT sensors can be embedded in building materials to track their performance over time. This data can be used to identify potential issues, such as materials degrading faster than expected, allowing for timely interventions and reducing waste.

Waste Reduction

Predictive analytics help construction teams to reduce waste and increase the management of resources. By analyzing data from previous projects, the predictive model can predict the number of materials required for a particular project and reduce the chance of overordering and minimizing the amount of waste.

For example, AI algorithms can analyze previous data about materials to determine the quantity of each item that is required to complete a project. This makes sure that items are purchased in the right quantities, which reduces the amount of waste and also lowers costs.

Enhanced Safety and Risk Control Using Technology

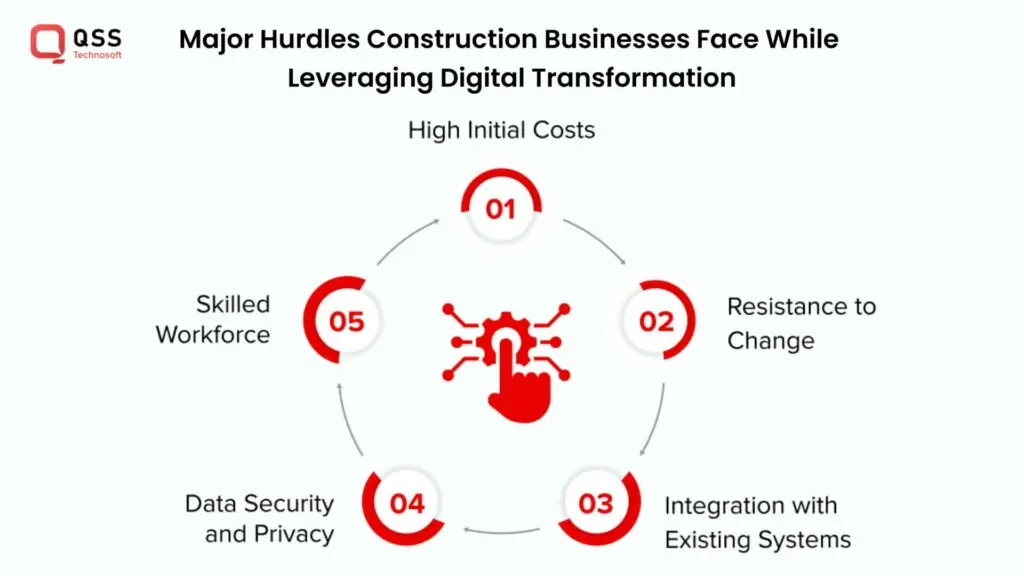

There are numerous hurdles that comes in path of construction businesses, such as –

This is how Digital transformation can solve such problems-

IoT for Worker Safety

IoT-enabled sensors improve worker safety by monitoring the hazards to workers and environmental conditions in real time. They can identify dangerous situations, like excessive temperatures or toxic gasses that alert supervisors and workers to respond.

For instance, IoT sensors can be worn by workers to track their vital signs and to detect symptoms of fatigue or heat stress. If the sensor detects an employee’s heart rate is excessively high or they’re dehydrated, it could notify the supervisor of the worker, allowing them to intervene prior to an accident occurring.

AI for Predictive Risk Analysis

AI is being utilized for predictive risk analysis that leverages data to spot dangers and avoid accidents before they occur. Through the analysis of data from previous research projects AI algorithmic algorithms are able to detect patterns, and can predict when accidents are likely to happen.

For instance, AI can analyze data about worker behavior or environmental conditions as well as equipment performance to pinpoint possible risks. The information gathered could be utilized to design safety procedures and education programs that address particular risks that are related to a particular project.

Virtual Training Simulations for VR

VR training simulations provide employees with a safe and controlled space to learn procedures for safety and prepare themselves for high-risk situations. The simulations simulate actual scenarios, which allows workers to develop their skills without having to be exposed to the actual dangers.

For instance, for example, a VR simulation could be used to instruct workers on how to handle an emergency like a fire at construction site. By rehearsing such scenarios inside a virtual setting workers can learn the abilities needed to be able to effectively respond in the event of a real-life emergency.

Cost Reduction and ROI Advantages of Getting Digital

Reduction in Operating Costs

Digital technologies are bringing significant savings in costs by enhancing efficiency, reducing waste, and reducing interruptions. Automatization, real-time monitoring, and predictive analytics all contribute to a reduction in operating expenses.

For instance, using IoT sensors that monitor the performance of equipment can help reduce maintenance costs by identifying possible problems before equipment malfunctions. This can reduce downtime and increase the life span of machinery and can result in significant savings in costs.

Return on Digital Investments

Studies have revealed that companies that adopt digital technology have experienced a significant increase in the value of their investment. For instance, the construction company that used BIM along with IoT technologies saw an increase of 20% in project delays as well as an increase of 15% in overall project profit.

These results highlight the power of digital transformation not only to enhance project outcomes but also to provide a significant Return on Investment.

Also Read:- Blockchain and AI: Innovative Ways They Can Work Together Shape

Conclusion: Creating the Future of Construction

Digital transformation is changing the construction industry by providing solutions to long-standing issues and opening the way to an efficient, safe, and sustainable future. From BIM and IoT to AI and robotics, the technologies that are driving this change are providing huge benefits in terms of construction efficiency as well as sustainability and safety.

While the industry of construction continues to develop in the coming years, it is imperative for businesses to adopt the latest technologies and to invest in the expertise and capabilities required to thrive in the digital age. When they do this, they will not just increase the quality of their work but also ensure long-term success in a competitive market.

We are proud to mention that our work has been recognized by leading B2B reviews and research platforms like GoodFirms, Clutch, MirrorView, and many more.

Digital Transformation in Construction: Shaping the Future